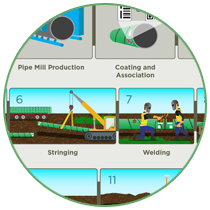

Integrated Services

At Stupp, our customers’ needs are the core of everything we do. From our custom pipe sizes and flexible scheduling to our integrated service offerings, Stupp’s goal is to streamline your project from specification to commissioning. International pipeline operators and small midstream companies alike know that they can rely on Stupp to deliver on our commitments and provide creative solutions to complex challenges.

- On-Site Coating

- Welding Solutions

- Logistics

- Storage

- Offloading

- Field Service

- Inspection

- Traceability Solution

Traceability Solution

To help our proactive customers meet PHMSA’s traceable, verifiable and complete requirements, Stupp is proud to offer full mill integration with SPOT, the industry standard in materials traceability solutions. SPOT is an intuitive, iOS-based technology that creates an electronic trail of your pipeline’s pedigree from steel melt to the ditch. This scalable solution is designed to meet the needs of any operator regardless of size, providing a cost-effective, standardized set of materials data for all projects. See how SPOT can add value throughout an organization, from procurement and logistics to construction and integrity.

To help our proactive customers meet PHMSA’s traceable, verifiable and complete requirements, Stupp is proud to offer full mill integration with SPOT, the industry standard in materials traceability solutions. SPOT is an intuitive, iOS-based technology that creates an electronic trail of your pipeline’s pedigree from steel melt to the ditch. This scalable solution is designed to meet the needs of any operator regardless of size, providing a cost-effective, standardized set of materials data for all projects. See how SPOT can add value throughout an organization, from procurement and logistics to construction and integrity.

On-Site Coating

To help our customers reduce costs and expedite time-to-market, Stupp Coatings operates a state-of-the-art coating plant adjacent to the pipe mills in Baton Rouge.

Coating Types

- Standard Fusion Bond Epoxy (FBE) for corrosion resistance

- Dual Layer FBE for high temperature applications

- Abrasive Resistant Overlay (ARO) for physical protection in rugged applications

- Internal Coating for flow efficiency and corrosion resistance

- Concrete Weight Coating for decreased buoyancy and mechanical protection

- Outside Diameter

- • 8" to 48"

- Coating Thickness

- • up to 40 mils

- Length

- • up to 80'